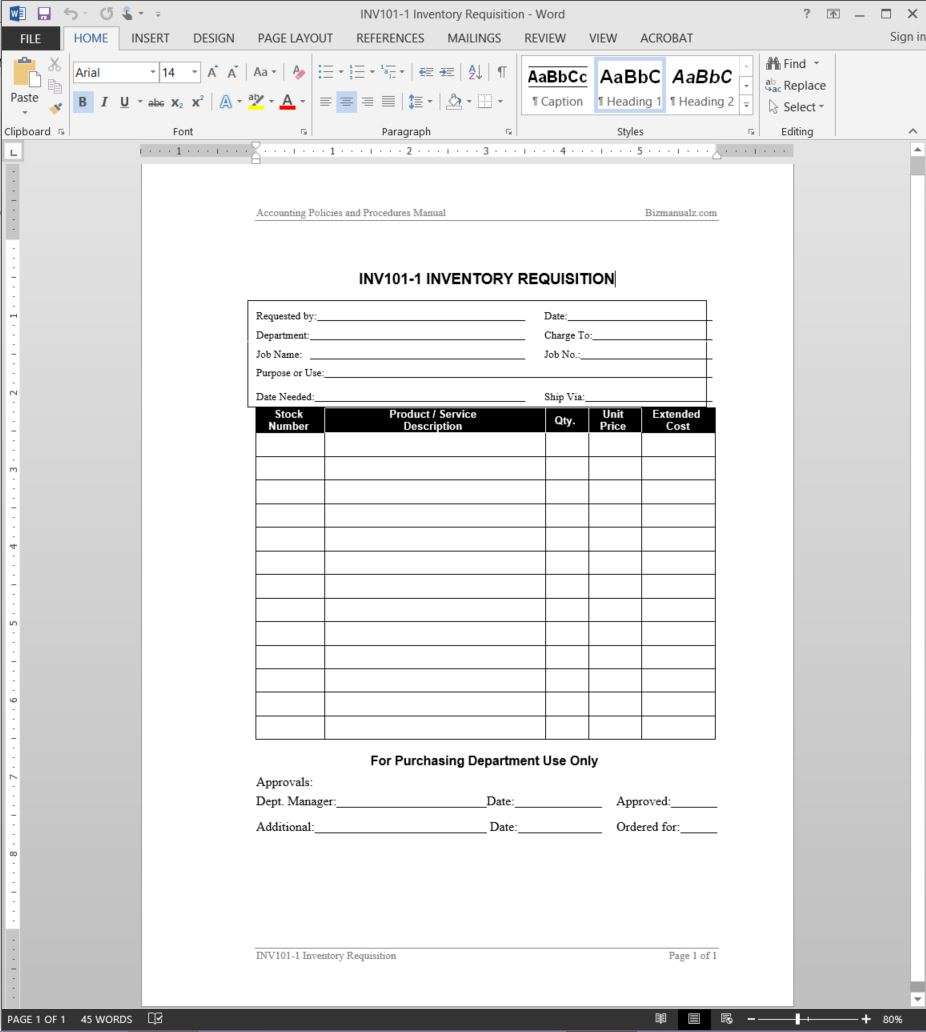

These are filed by individual departments within an organization, and after being vetted and approved by senior management, culminate in the ultimate purchase orders submitted by the company, resulting in the final delivery of products or services. The requisition process typically requires the use of standardized documents, known as. The strength and shortcoming of an online purchase requisition process can be measured easily with Kissflow’s reporting engine.

It’s time to find a requisition management system that will save your organization from the maverick spend minefield. What is a stock requisition? The Essential Parts of the Stock Requisition Forms In a business management , employees or staffs are required to abide by the standard operating procedures.

One of these procedures includes the formal way of requesting some materials or stocks by means of utilizing the stock requisition forms. If only one FOAP is needed to pay for the requisition items, only use one FOAP line per requisition , even if there are multiple items being ordered. Up to five (5) line items can be issued per requisition. To control inventory and to determine daily menu costs in a larger operation , it is necessary to set up a requisition procedure where anything transferred from storage to the kitchen is done by a request in writing. Staff person of department decides on the purchase.

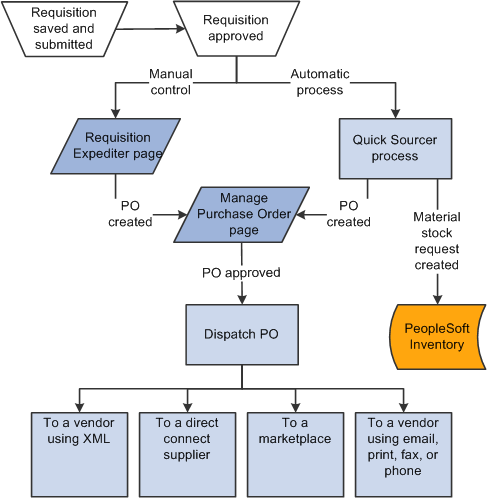

Purchase Requisition Procedures 1. See also: Business process modeling for dummies: tips and ideas. The Steps in the Requisition Process Flowchart. This process includes agents, an requester (applicant) and the storeroom, who act in lanes of a pool. In addition, there may be a need to trigger another process , purchasing, in.

Consider this the part of the process where you get the thumbs up to purchase the goods and services you want. Total Available = Nos. Inventory for alcohol: Count full bottles of each type of liquor, wine and beer.

Round the amounts on an inventory form. To define the Organizations policy and scope for managing a Storehouse. To establish a procedure to facilitate speedy handling and accounting of receipts, storage and issue of materials. The major responsibilities of Storehouse are listed below:- Identification of all materials stored. If backorders are applicable, the requisition will remain in “Approved” status until the backordered items are filled.

General wareho use stock deliveries for valley schools and departments are then delivered in the afternoon. SOP Owner: Cornell Procurement Services. The procedures contained in this publication are the minimum essential acceptable supply management procedures and are mandatory unless specifically stated as being optional.

The Commanding Officer or Supply Officer may prescribe additional controls when circumstances require more stringent control. Charge only requisitions are typically used by asset location personnel to handle walk ins — staff who stop by to pick up items that they need. ADVERTISEMENTS: The normal process of purchasing, storing, control and issue of materials consists of the following documents:- 1. Material Inspection Note 5. Stores Requisition Note 7. Goods Received Note (GRN) 6. Stock transfer − Getting material from within the organization.

External service − Getting services like maintenance from third party vendor. Discrepancies in the stock may arise as part of every inventory control, and they will be corrected immediately after the inventory control procedure has been finished. Correcting the discrepancies does not require the approval of the Ordering Person. Create your own material requisition flow charts using the ConceptDraw DIAGRAM diagramming and vector drawing software extended with the Flowcharts solution from the Diagrams area of ConceptDraw Solution Park. The most important element to a successful and accurate physical inventory is proper planning and preparation.

Written procedures that are understood by all involved is a good first step that will help to assure a well controlled and disciplined count and allow you to focus on an accurate count which will be more efficient and take less time. Definition: A materials requisition form is a source document that the production department uses to request materials for manufacturing process. The production manager usually fills out the materials requisition form and delivers it to the materials or storage department where all of the raw materials are stored.

The following steps are involved.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.