Basically, I’m looking for some solid feedrate suggestions for both hogging MDF and hardwoods. Starts making chattery noises, yet I see people running. Powerful dust collection is a must, for safety. See full list on pub. What is CNC feeds and speeds?

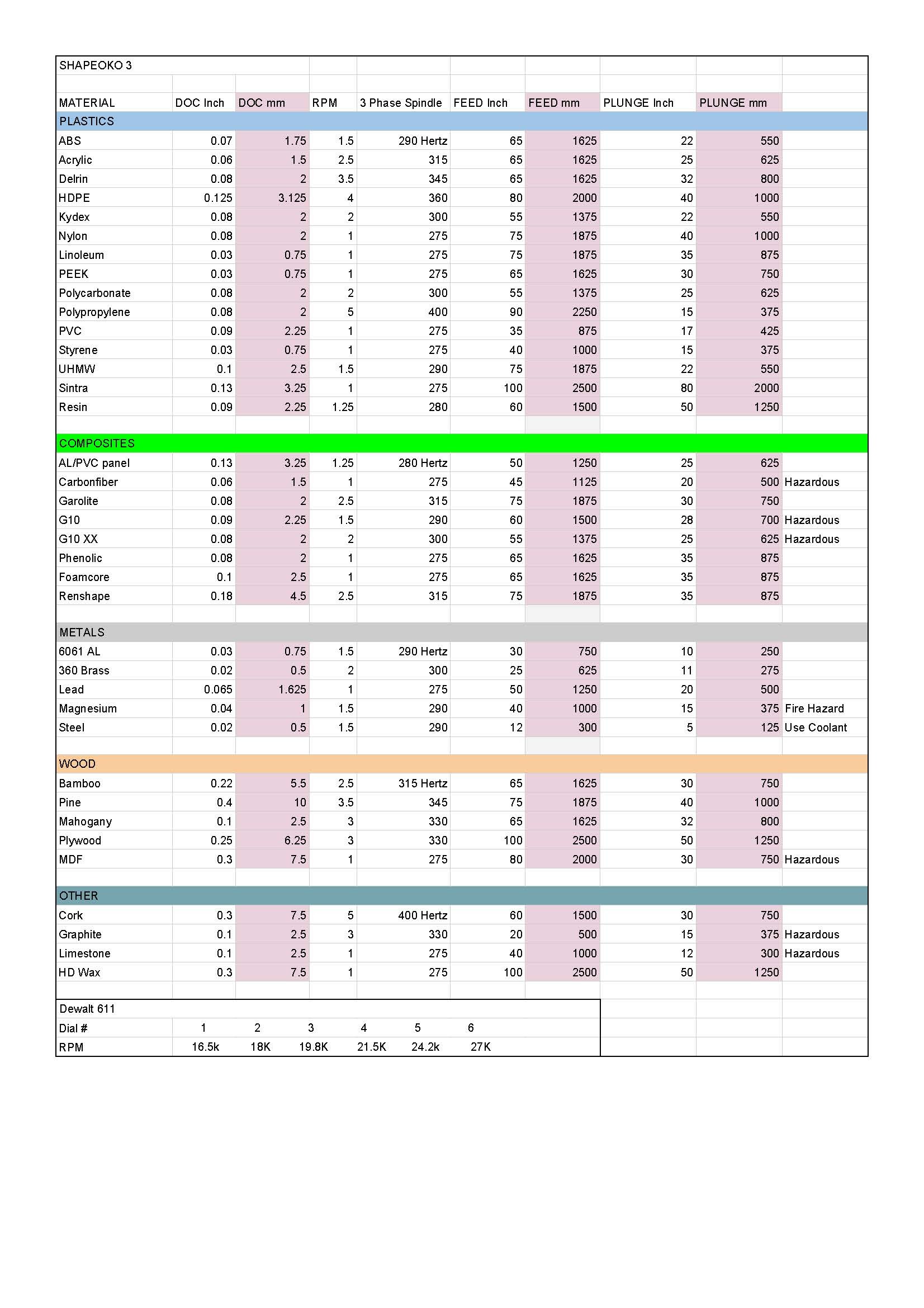

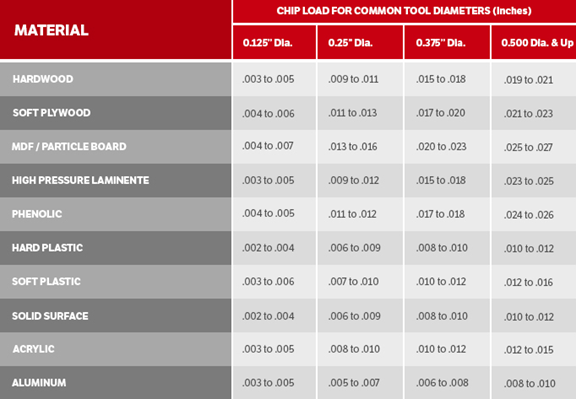

It turns out that the characteristics that affect the feeds and speeds for wood are different than hardness. They have to do for example with the behavior of the sap relative to the sawdust and how the chips are made. Optimizing feed rates and speeds : 1. Start off using an RPM derived for the chip load for the material being cut (see charts).

Increase the cutting speed ( feed rate) until the quality of the part’s finish starts to decrease or the part is starting to move from hold downs. Then decrease speed by. To calculate feed rate select a specific RPM from the range below. Please remember that if you are using the higher RPM, the friction will give a better surface finish but can create more mechanical wear on the tool edge so you should always be aiming for the lowest RPM for that tool and material.

Twist Drill Feeds and Speeds : Delving into the considerations for twist drill feeds and speeds. V-Bits, Dovetails, and Other Exotic Cutters: Finding feeds and speeds for these less often used cutters. Advanced High Speed Machining: Tool Engagement Angle, Trochoidal Milling, Peeling, and all that Jazz. Milling Speed and Feed Calculator Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill.

The feed rate represents how fast the machine will move the router bit though the material when cutting and is critical to get right for leaving a good quality cut edge. Here are some speeds and feeds you can use for it. Learn more about our. Feed is generally measured in Inches Per Minute (IPM) and speed is measured in Surface Feet per Minute (SFM).

A feed of IPM would drive a tool inches in one minute. If you took an end mill and rolled it along the floor like a tire at 1SFM it would travel 1feet in one minute. Max Rpm and watch for the surface finish. If it is too rough slow it a bit. That gives me a chipload of 0. Using a 1-flute cutter, I normally run at 5-ips at 10RPM to get the same chipload.

GRBL spindle speed issue. Advice on bit selection, feed speeds , RPMs, and other parameters for working with laminated or melamine-surfaced MDF panels on a CNC router. ProvenCut gives you the information you need to succee including direct links to the tools used. This speed is termed ‘spindle speed’ and is directly related to the feed rate or surface spee which most machines are capable of doing up to about 200ipm. If you are using the DeWalt 6(110v) or 6(220v) router that comes with your X-Carve, the spindle speed varies from 10RPM at the lowest setting (1) up to 20RPM at the highest setting (6).

We recommend staying between the first and second settings for most projects. Carvey’s spindle speed is 10RPM. Therefore, your Feed Rate should be 6inches per minute. You already know that you want to use a Feed Rate of 6inches per minute, and a speed of 10RPM. The final piece of the puzzle for laser processing is the cutting speed.

Approximately of the time while the program is running the laser is cutting, this is the majority of the processing time. The cutting capabilities of the laser is directly proportional to the beam quality and beam waste of the laser.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.