What is the feed rate for milling? How do you calculate cutting speed? How to calculate feed speed? This calculator will determine speeds and feed rates for machining operations on mill or lathes.

SMM = surface meters per minute. Radial Depth of Cut in Percentage of Diameter. CLF = chip load factor. These calculations are based upon theoretical values and are only intended for planning purposes.

Free Shipping Available On Many Items. Money Back Guarantee! But Did You Check eBay? Flood coolant recommended.

In the metric system, the feed rate of the cutter can be calculated for each revolution of the cutter. You can rely on data from the Tooling Catalog feeds and speeds chart. Please include as much information about the material you are machining as possible. That data is important, but used by itself, it’s also loaded with limitations.

It can only cover variables. On a rotary tool such as a drill or end mill , this is a measure of how fast its periphery spins relative to the workpiece clamped to the table. Cutting speeds are specified in feet per minute (imperial measure), or meters per minute (for metric ). Italian Olive by Cookwoods. HSS cutter set your spindle speed from 4to 6rpm. Need to calculate your milling speed , feed , surface feet per minute or inches per tooth?

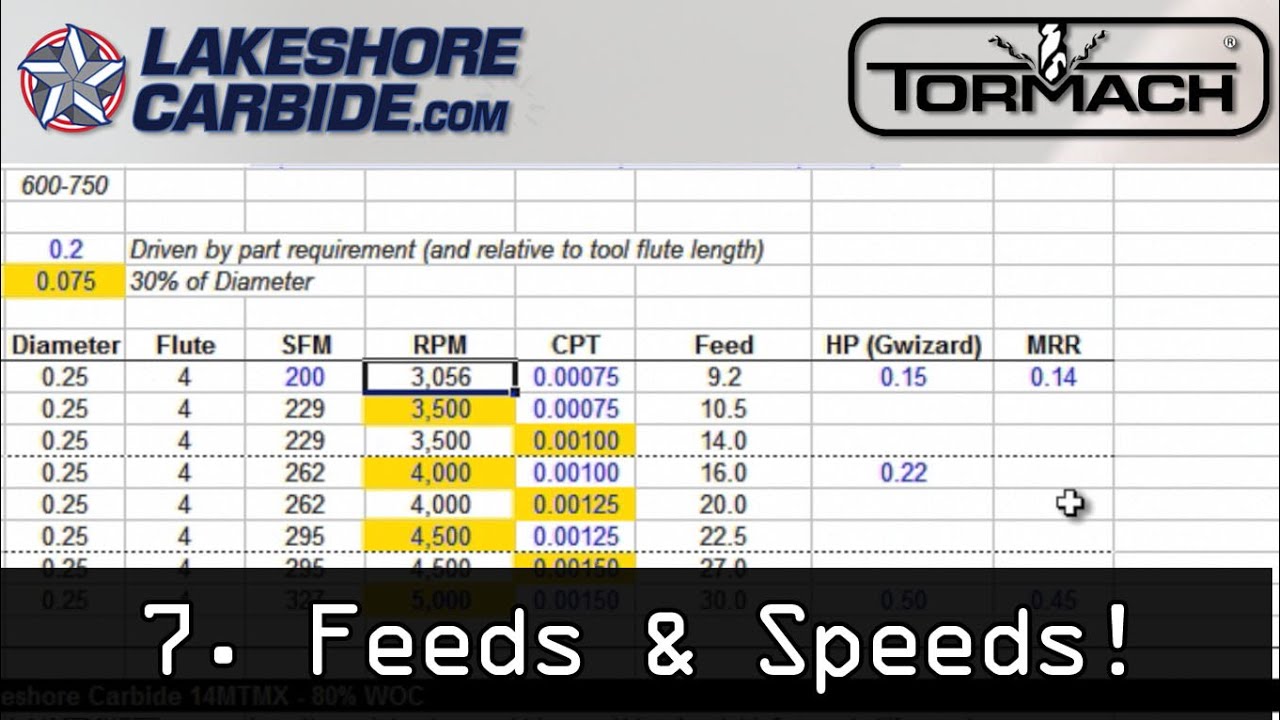

Click here to download a printable PDF file of this chart. Each individual application is different than the next. Rigidity of workpiece, tool holders, etc. Optimizing feed rates and speeds : 1. Start off using an RPM derived for the chip load for the material being cut (see charts ). Increase the cutting speed ( feed rate) until the quality of the part’s finish starts to decrease or the part is starting to move from hold downs. Then decrease speed by.

For AD equal and above Tool Dia. Feed at Suggested Value. X Highest Speed Range. Answer) Calculate table feed per min vf=0.

Determine the spindle speed (RPM) and feed rate (IPM) for a drilling operation, as well as the cut time for a given cut length. Drilling operations are those in which a cutting tool with sharp teeth, such as a twist drill, rotates and feeds into the workpiece axially, forming a hole with a diameter equal to that of the tool. Calculate feed and speed for CNC cutting tools, machines and projects with our free calculator below. All you need are the speed RPM, number of flutes, material and tool diameter. CNC Router bits and CNC router tools are effective, only if used in the correct manner.

If the material you need is not liste let us know and we can help you find. A customer can find the SFM for the material on the left, in this case 3stainless steel. It is established using the values for cutting depth, width and feed. Specific cutting force, k ct.

Machining time, T c (min) Machining length (l m) divided by the table feed (v f). When milling or drilling, or creating a tool path for a CNC machine the feed rate must be determined. Materials have rated surface speeds for a given type of cutter. The harder the material the slower the speed. The number of revolutions the milling tool makes per minute on the spindle.

This is a machine-oriented value, which is calculated from the recommended cutting speed value for an operation. A value for calculating the table feed. The feed per tooth value is calculated from the recommended maximum chip thickness value.

Speeds must be reduced as length of hole increases. Holes, taps with tapered chamfers are able to operate faster than taps with bottoming chamfers. Vertical tapping speeds can be increase compared to horizontal tapping.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.