Use a plunge rate of or less of the feed rate. So for a feed rate of. See full list on pub. Please remember that if you are using the higher RPM, the friction will give a better surface finish but can create more mechanical wear on the tool edge so you should always be aiming for the lowest RPM for that tool and material. For deep slots reduce the Ft.

Reference: Erik Oberg, et. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. To do this, download the Acrylic Custom Tool Library , which contains all the recommended feeds and speeds for this material.

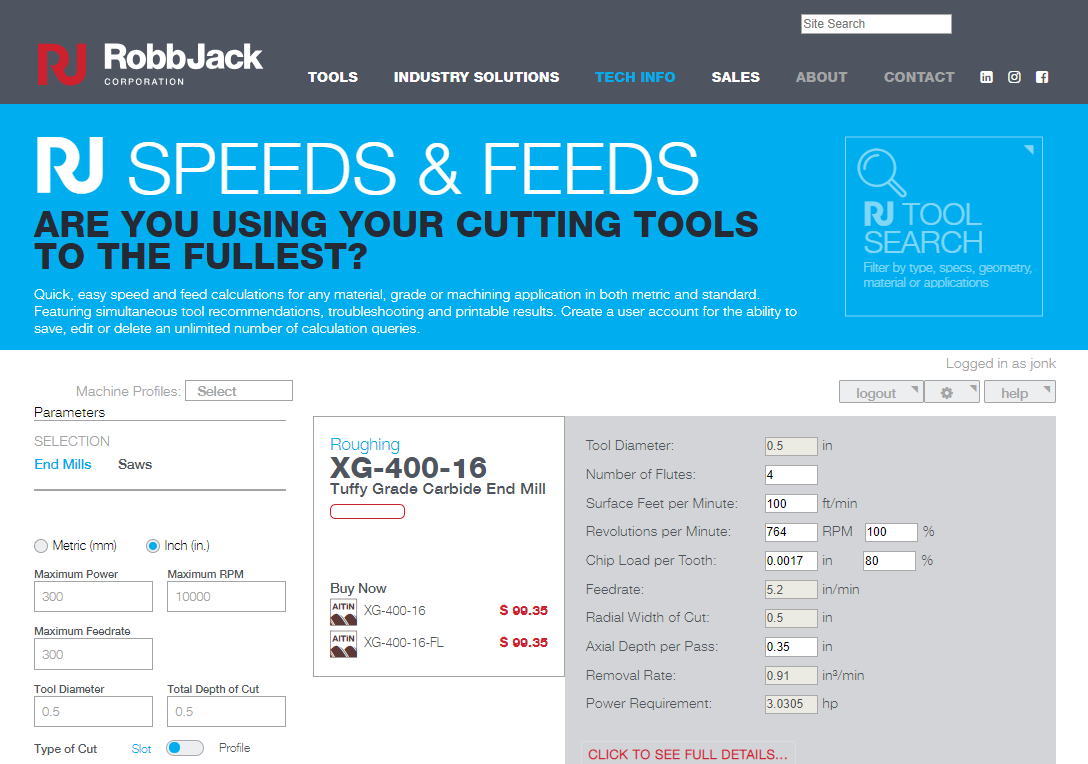

Three ball bearings provide support for heavy duty load and high speed. However, there are some basic things you need to know in order to ensure success and give you a smooth finish when cutting Acrylic on your STEPCRAFT CNC system Unlike woo Acrylic will have a “sweet spot” in terms of speeds , feeds , and depth per pass that you want to be aware of. Below are important guidelines. For AD equal and above Tool Dia. This calculator will determine speeds and feed rates for machining operations on mill or lathes.

Feed at Suggested Value. Cutting speeds are usually given in feet or meters per minute and these speeds must be converted to spindle speeds , in revolutions per minute, to operate the machine. Drilling operations are those in which a cutting tool with sharp teeth, such as a twist drill, rotates and feeds into the workpiece axially, forming a hole with a diameter equal to. Onsrud bits are typically allowed a cut depth per pass equal to the cutting edge diameter unless otherwise specified. For a deeper cut, it will be necessary to reduce the chip load.

But which one is right for you? We offer both a free online feeds and speeds calculator that uses the simple formulas taught in shop class. I just got into V-Carve and need some help. I know feeds and speeds and stepover are a nonstop topic among CNCers, but I need a bit of guidance on feed , speed , and stepover for a v-bit.

Generic work, generic degree bit. I can learn and adjust as I go, but I need help finding a place to start. In general, use tools with a high positive or high shear cutting geometry.

Plastic material that is fixtured properly, either with pneumatic clamps or a vacuum chuck, can be face milled with high speeds and feeds. The DATRON double flute end mill with edge radius and polished flute is designed with an. The guide speeds above are only a starting point.

Depending on the machine and material, you may get a better finish by running faster or slower. The best indication of quality is the noise made when cutting and you soon get to know the sound of a ‘good’ noise. Reduce speed and feed by when reamed hole size comes out too big With Carbide drills always check the manufacturers recomendation on what drilling cycle you should run. Turning operations remove material from a rotating workpiece by feeding a single-point cutting tool axially, along the side of the workpiece.

Calculate Spindle Speed Variables. Optimizing feed rates and speeds : 1. Start off using an RPM derived for the chip load for the material being cut (see charts). Increase the cutting speed ( feed rate) until the quality of the part’s finish starts to decrease or the part is starting to move from hold downs. Then decrease speed by. The folks over at LMT Onsrud have put together a short refreshe.

I was wondering if the same existed for non metal materials. Router at super high speeds throws a lot of air at the cutting zone.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.