It’s a matter of using the right cutter or bit, the correct feeds and speeds , and avoiding various other pitfalls described in this article. It is all about matching the capacities of the machine to the sweet spot speeds and feeds requirements of aluminum through a clever selection of cutting and tooling parameters. Put enough lubrication and clear the chips out, and you are good to go.

The feed rate represents how fast the machine will move the router bit though the material when cutting and is critical to get right for leaving a good quality cut edge. Using a ⅛” (.125”) diameter cutter instead of a ¼” (.25”) cutter the required RPM for aluminum example will be:- 500SFM X 3. The next issue would be the feedrate. Can you use a CNC router for aluminum?

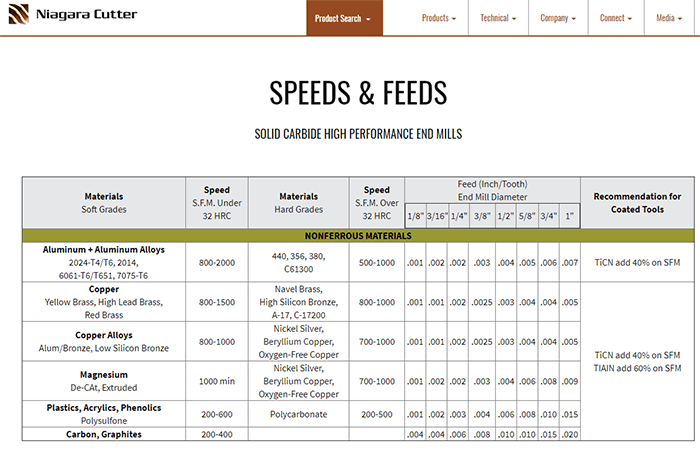

What are CNC endmills used for? Are downcut cutters made of aluminum? Optimizing feed rates and speeds : 1. This works particularly well for routers. Start off using an RPM derived for the chip load for the material being cut (see charts). Increase the cutting speed ( feed rate) until the quality of the part’s finish starts to decrease or the part is starting to move from hold downs.

You’re going to want to use some kind of lubrication for aluminum. You can get by without anything for a short amount of time, but it’ll be riskier the longer you go without. If you’re planning on letting your router buzz away for hours unattende don’t expect your cutter to still be in one piece when you get back if it’s run dry. There are a lot of websites and forums that say that oil mist is required for cutting aluminum.

It’s really not a bad idea, though. If you want to do the upgrade and have the resources to pull it off, I’d definitely recommend installing one. I use mine all the time for plastics and metals. They’re not hard to set up.

All you need is a kit, compressed air and a bit of oil. The whole package will cost you under $1(assuming you have an air compressor), so if you use your router reasonably often it’s a really smart upgrade. While it definitely is my preferred way to cut it, there are a few alternatives that also work great. Probably the simples. See full list on makeitfrommetal.

For the heavy duty CNC milling machines at work, my go-to was a 1″ diameter solid carbide roughing endmill for tough alloy steels. Obviously, that wasn’t going to work for a little hobby router. Small tools work much better – but even still you need to know what kindof tool to use for aluminum. Here are the basic qualities you want out of a cutting tool for aluminu1. Great chip clearance – aluminum is gummy stuff that loves to plug up cutters, so the best way to handle it is with cutters with a lot of space between the flutes for the material to clear out while cutting.

Strong tool – aluminum isn’t a hard metal, but you can still easily break a cutter on it. The flute endmills that are popular for plastics often aren’t strong enough for aluminum 3. The cutting parameters and quality of cut will depend a lot on how rigid your machine is. Small hobby routers and the big $100k machines are very different.

If you push it too fast, you might actually be able to see your machine flex under the loa if not rattle loose. Aluminum needs a lot more rigidity that wood or plastic. Here are some tips for dealing with a machine that’s not too rigid: 1. The longer the bit, the more leverage the workpiece has. When you’re buying bits, keep an eye out for “stub end” endmills.

Keep them nice and short in the collet. Use a really small depth of cut. For my first machine (before I did a bunch of upgrades to make it more rigid) I could only go down about 0. Z when cutting aluminum.

The nice thing about using small Z depths is that you can usually crank the feed rate. Consider taking measures to boost your machine rigidity. This is usually the first question aske but the least likely to get a straight answer.

CNC mills and lathes are generally very predictable in how rigid they are. That’s why we can calculate optimal speeds and feeds without too much testing. A homemade hobby router will be very different from a large router that’s professionally built for aerospace composites. Either way, there are a few starting points that might work for you. The textbook cutting speed for aluminum using a carbide tool is about 5surface feet per minute at the high en and 0at the lower end.

That’s not to say that you can’t spin it slower – you definitely can. But usually you don’t want to go faster than that. So here’s how that translates to endmill RPNow it’s pretty unlikely that you have a 90RPM machine,. Toolpaths are actually pretty important for routing aluminum.

Avoid plunging down into the metal whenever possible. Some tools are better designed for this that others, but it’s generally best avoided entirely. Unless you’re dealing with very thin sheet metal, that is. Then it’s not a big deal. If possible, get to your Z cut level off the workpiece, and then start cutting.

Sometimes you need to get the tool in from the middle of a thick sheet. If it’s heavy aluminum, try not to just jam the tool straight down. Generally, there are two common ways of achieving this: A ramp-on-shape type of engagement, or helical interpolation. For a ramp on shape motion (some CAM software might call it something different) you’ll trace the profile that you’re wanting to cut while the tool slowly descends.

It’s typically something like a zigzag motion. If the material you need is not liste let us know and we can help you find the right speed and feed for your piece. In this article, I will cover each and walk you through the optimal settings that we found work best on a STEPCRAFT CNC.

Speed and Feed Calculator for Drilling and Milling,easyspeedsandfeeds. The Carve King rules the competition. Get Same Day Shipping And A 90-Day Guarantee. Shop Top Woodworking Products Now!

I have found that milling aluminum at speeds and feeds you would expect to use on a soft alloy steel on an industrial machine will produce effortless. Speeds and Feeds for Drilling Although I suggested only using carbide for your endmills, high speed steel (HSS) drill bits will work perfectly fine. Hence, it is best to use Feeds and Speeds Calculator, to ensure accuracy during this job. If you are using a HSS drill, the drilling speed for aluminum is 2SFM. The tool feed in case of end mills for aluminum should be 0. Well, here is the main part which you have been waiting for.

You want the best CNC aluminum router for you, right? I have listed below the best CNC routers for aluminum. This post should give you a head start.

Perfect for CNC beginners, carbide 3d shapeoko, and inventables xcarve users. Spindle speed is the rotational speed of your bit, measured in revolutions per minute (RPM). Get the best value in CNC with MillRight CNC. We Are The Purveyors Of Fine Machinery.

Order Your Industrial Tools At Grizzly!

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.