Alloy steels : 50–120. Free cutting steels : 115–230. Optimizing feed rates and speeds : 1. Start off using an RPM derived for the chip load for the material being cut (see charts ). Increase the cutting speed ( feed rate) until the quality of the part’s finish starts to decrease or the part is starting to move from hold downs.

Then decrease speed by. WORKPIECE MATERIAL CUTTING SPEED (SFM) TIALN EXAMPLES This chart provides starting parameters for calculating speeds and feeds. Actual feeds and speeds will depend on many variables including machine tool condition, rigidity, workpiece size and shape, tool extension, depth of cut, etc.

Twist Drill Feeds and Speeds : Delving into the considerations for twist drill feeds and speeds. V-Bits, Dovetails, and Other Exotic Cutters: Finding feeds and speeds for these less often used cutters. Advanced High Speed Machining : Tool Engagement Angle, Trochoidal Milling , Peeling, and all that Jazz. What is the feed rate for milling?

How do you calculate cutting speed? How to calculate feed speed? Milling Speeds and Feeds Charts The most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate.

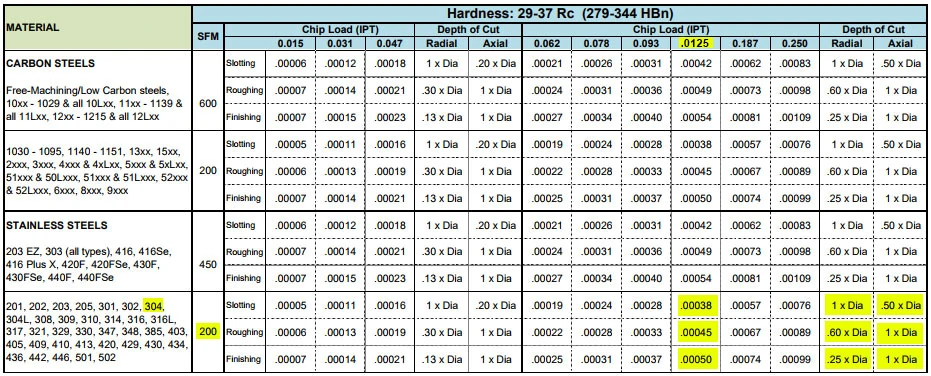

We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills. Please include as much information about the material you are machining as possible. Radial Engagement Feed Adjustment Chart Click here to download a printable PDF file of this chart. Note: All speed and feed data are suggested starting points. They may be increased or decreased depending on machine condition, depth of cut, finish require coolant, etc.

Italian Olive by Cookwoods. Here’s your comprehensive guide to Feeds and Speeds for Woo together with Tips and Techniques that are specific to cutting wood on a CNC Machine. Use these charts for carbide tipped milling cutters.

MADE IN USA ROCK RIVER TOOL, INC. METAL MILLING SPEED CHART - PDF Printable Metal cutting milling speeds for different materials. The chart is based on mild steel to the hardest tool steel milling applications. The column of the milling chart list the Brinell Hardness, material condition and the SFPM for HSS and Carbide tools. Suggested speeds are to 1 higher than the suggested speeds for cutting taps in similar applications.

PIPE TAP SPEEDS should be between one-half and three-quarters of the speeds of taps of comparable diameter and pitch. Countersinks Deburring Tools Drills End Mills Grooving Systems. You can rely on data from the Tooling Catalog feeds and speeds chart.

That data is important, but used by itself, it’s also loaded with limitations. It can only cover variables. Our G-Wizard Feeds and Speeds Calculator covers variables! Since machining centers don’t have gas pedals (nor gages that announce the current cutting speed ), spindle rpm is the value we have to plug into the CNC program. To determine this (you might need to break out the calculator), simply multiply the recommended cutting speed by the value 3. Depending on depth, use diameter at top of part to determine chipload.

For deep hole drilling reduce speeds by for 3xDiameter, for 4xDiameter, for 5xDiameter and for over 6xDiameter. Drilling speeds and feeds are based on jobber length drills. Important Disclaimer: The Accupro speed and feed rates are suggested by the manufacturer as a general guideline. A customer can find the SFM for the material on the left, in this case 3stainless steel. Recommended cutting speeds are given in charts.

In Table you will find a typical recommended cutting speed chart.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.